Kalibraatio: The Simple Guide to Keeping Your Tools Accurate & Safe in 2025 – For Labs, Factories & Everyday Pros

Kalibraatio is the simple process of checking your measuring tools against a perfect standard to make sure they give the right numbers every time. You take something like a scale, put a known good weight on it, see what it says, and fix it if it’s off. This keeps everything accurate and safe in places like factories and labs. It’s called laite kalibraatio when you do it on devices, mittalaitteiden Kalibraatio for any measuring gear. Wrong tools can cause big problems like wasted materials or bad test results. Kalibraatio stops that by making sure your numbers are always true. Rules like ISO standards say you have to do it regularly. If you’re a worker, boss, or tech person, this is your key to good work without surprises.source1

Why Kalibraatio Matters in 2025

Bad measurements cost companies millions every year – one factory lost $10,000 from a single off-sensor. Kalibraatio keeps work safe by catching errors before they cause accidents or recalls. It saves money too: less waste, fewer fixes, happier customers. Labs need laboratory calibration for true science results. Factories rely on teollinen Kalibraatio for big machines. Rules require a certified Kalibraatio with papers to prove everything is right. In 2025, smart tools with sensors will make it even more important. Do it right and your business runs smoothly, passes checks, and grows strong.

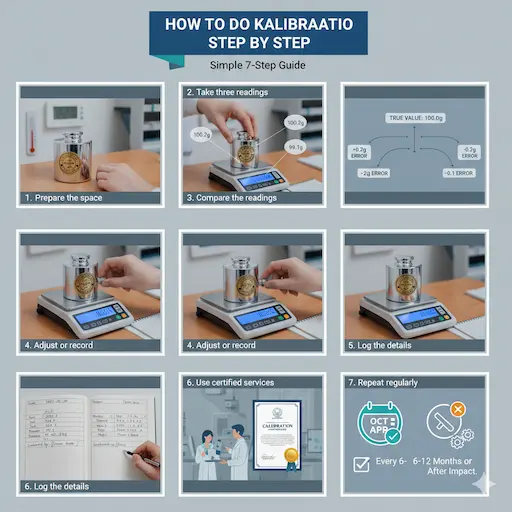

How to Do Kalibraatio Step by Step

Here’s a simple step-by-step version:

1. Prepare the space: Choose a quiet room at a normal, stable temperature. Have your tool and a trusted standard such as a certified weight ready.

2. Take three readings: Place the standard on the tool three times. Write down each result.

3. Compare the readings: Calculate how far each reading is from the true value. This shows the error.

4. Adjust or record the correction: If your tool allows adjustable calibration, use the knobs to bring it closer to the correct value. If it cannot be adjusted, record the correction you need to apply in future measurements.

5. Log the details: Write the date, results, adjustments, and your name in a calibration log.

6. Use certified services when needed: For certified calibration, send the tool to a professional who issues a formal certificate.

7. Repeat regularly: Do this every six to twelve months or after the tool gets dropped or bumped. This keeps measurement errors low and helps maintain good accuracy.2

Types of Kalibraatio for Different Jobs

Laitekalibraatio is for single devices like scales or thermometers – quick and basic. Teollinen Kalibraatio handles big factory stuff like robots and sensors in production lines. Laboratoriokalibraatio is super exact for lab tools measuring tiny things. Anturien Kalibraatio checks sensors in cars or machines for heat, pressure, or speed. Tarkkuuskalibraatio is high-precision for science and tech. Kalibraatio ja testaus combines checking with full tests. Standard isoitu Kalibraatio follows ISO 17025 rules for global standards. Pick the type that fits your work to stay compliant and accurate.

Easy Examples of Kalibraatio in Action

For anturien Kalibraatio, take a car temperature sensor: compare to a known hot water bath, adjust if wrong. In labs, laboratory calibration for a pipette: measure water drops against perfect weights. Factories do teollinen Kalibraatio on assembly lines: check robot arms with laser standards. Health care: blood pressure machines get laite kalibraatio with certified pumps. Food industry: scales for ingredients to avoid over-/under portions. Each example shows how Kalibraatio stops mistakes and saves cash.

Good Things from Regular Kalibraatio

Measurement accuracy means your numbers are always spot-on, no guesses. Equipment reliability keeps tools working longer without breaks. Regulatory compliance for devices helps pass government checks easily. Sensor performance validation makes sure tech like alarms work when needed. Quality assurance builds trust with customers. Factories cut downtime, labs get true data, and businesses save big on fixes. In 2025, it will even help with smart AI tools that need perfect inputs.

Kalibraatio in Factories & Labs

In factories, teollinen Kalibraatio checks big sensors and machines to keep production smooth – like verifying pressure gauges in pipes. Labs use laboratoriokalibraatio for microscopes and balances to make sure research is real. Metrology and instrumentation is the tech name for all this measuring science. Industrial sensor verification stops bad products from shipping out. Precision testing in labs avoids wrong diagnoses or failed experiments. Both jobs need Kalibraatio for safety and success.source3

Pick Good Kalibrointipalvelut

Look for services that follow ISO 17025 calibration standards – they’re the gold standard. They should give full calibration certificates with all details. Ask if they trace back to national labs for true accuracy. Check reviews from other factories or labs. Good ones come to your site for no downtime. Fast turnaround, fair prices, and expert teams make the best choice.

Mistakes to Skip & Best Tips

Don’t forget: set calendar reminders for every 6–12 months. Avoid hot/cold rooms – temperature messes up readings. Keep papers safe: lose calibration certificates and you fail audits. Train your team on the basics. For industrial and lab calibration, clean tools first. Do quick daily checks between full ones. Follow best practices like testing multiple times.source

FAQs

What is Kalibraatio?

Kalibraatio is checking tools against perfect standards to make sure they measure correctly. You test, see errors, and fix or note them. It’s essential for accuracy in every job.

Why do Kalibraatio?

It keeps work safe, saves money on mistakes, and meets rules. Wrong tools cause waste, accidents, or bad results. Regular checks fix that fast.

How often?

Every 6–12 months, or more if tools get heavy use or bumps. Follow your industry rules for exact times. Better safe than sorry.

Do it myself?

Yes for simple stuff, but pros for sertifioitu Kalibraatio with certificates. They have better standards and know-how for complex tools.

What is laitekalibraatio?

Laitekalibraatio is device-specific checking, like scales or sensors. Compare to known goods, adjust, and document for perfect performance every time.

Conclusion

Kalibraatio is the easy secret to accurate tools, safe work, and big savings in 2025. From simple home checks to pro lab and factory services, it keeps everything running right. Start today – check one tool, see the difference, and never look back4!

See more:

- https://leatheling.com/lyposingrass/

- https://leatheling.com/videoa/

- https://leatheling.com/olivia-rodrigo-house/